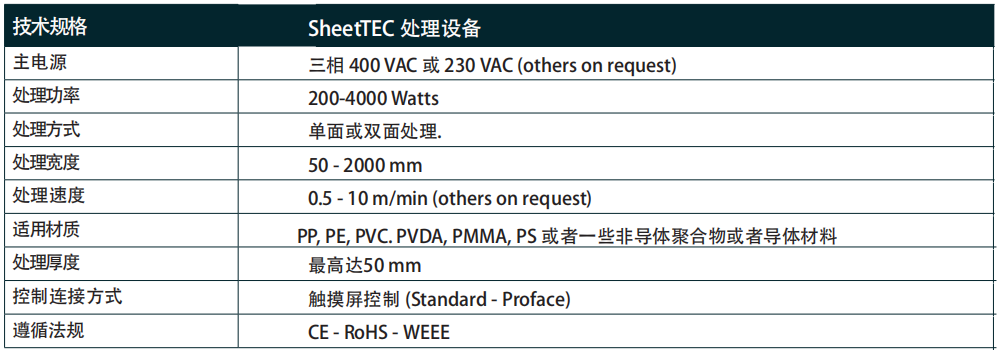

Treating Machine

SheetTEC

product features:

|

·Easy to install and use ·Single or double-sided processing ·Environmentally friendly ·Power density control ·Customized design ·Process control ·Effectively control processing costs |

|

Due to the low surface energy of the PP material, problems such as ink peeling and unsatisfactory bonding effects occur after printing or after glue bonding. In order to obtain the best bonding effect, improving the surface energy of the material becomes a vital link. The treatment with Tantec's corona equipment can significantly increase the surface energy of its materials and improve its adhesive properties.

SheetTEC flat / sheet surface treatment equipment can be freely adjusted for products with different sizes and widths, and the adjustment width can be adjusted from 50-2000mm.

SheetTEC flat / sheet surface treatment equipment can be used independently from the transportation line, or can be easily integrated into the current production line. At the same time, single-sided and double-sided processing systems can be provided according to customer requirements.

SheetTEC flat / sheet surface treatment equipment adopts metal electrode method to optimize the processing of non-conductive materials, while ceramic electrodes can be used as an option to process conductive materials such as aluminum alloy and stainless steel.

Due to the in-depth research equipment of Tantec high-pressure technology, the edges of the sheet can be evenly processed, and even slightly deformed edges can ensure the overall stability of the processing effect.

The processing speed of the equipment is between 0.5m-10m / min.

The stable power output of the equipment can ensure the consistency of the effect of 50mm thick material processing.

Features:

·Easy installation Just connect power.

·Single-sided / double-sided processing The device can provide single-sided / double-sided processing.

·Environmentally harmless treatment method Corona treatment of plate is considered to be an environmentally friendly process with lower operating costs.

·Power density control This system combined with HV-X series mainframe can realize the function of changing the output line speed and the output power automatically change to ensure the consistency of the processing effect under different speed conditions.

·Low-cost processing technology Only electricity can be used to achieve effective processing of sheets or plates, and the system can achieve 1-4KW power output according to different processing widths and speeds.

·Processing process monitoring The HV-X series host of this system is connected with PLC to easily realize the function of parameter setting and real-time monitoring of the equipment.

·Easy maintenance This equipment is easy to install, easy to operate and easy to maintain.

·Customized design The processing system can be specially designed according to customer requirements to achieve easy installation with existing or new products.